Present. Consistent. Reliable. Trusting our reputation and long-time presence providing construction management services on multi-million-dollar capital projects for the Hornell City School District, Welliver returned to North Hornell Elementary School to manage several initiatives funded under the Smartbond, capital outlay, and federal funding sources.

Our team managed the 10,000 square foot renovation of the originally constructed corridors throughout the entire one-story elementary building. Work included new ceilings, carpeted flooring, painting, and ceramic wall tile. The original building was constructed in 1962 with additions built in 1987 and 2003. One of the reasons the district approved the construction of this recent addition to the existing elementary school was the need to move students in 3PK through first grade from another location into one building and create a more cohesive academic environment.

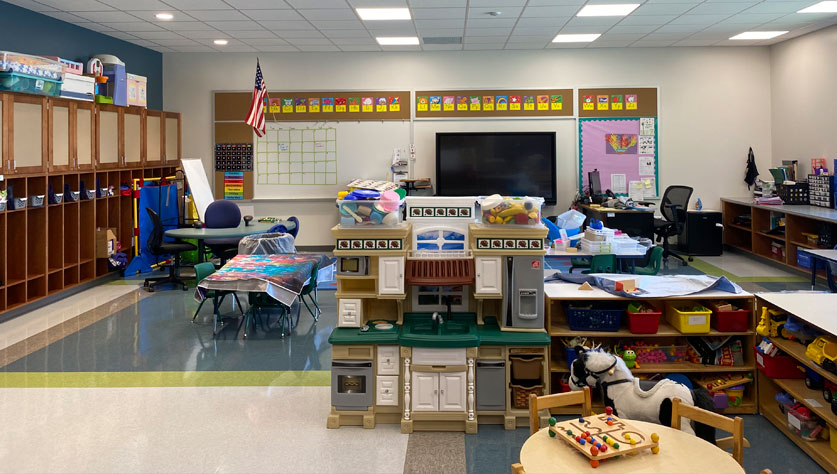

In addition, we removed an existing stage and renovated it into three (3) offices. The project also included the addition of two (2) classrooms with two (2) auxiliary spaces, large windows enabling lots of natural light, as well as new energy efficient lighting throughout the addition. Exterior site work associated with the new 4,300 square foot addition included the parking lot, new building steps and a handicapped accessible ramp, and landscaping. The project also included the two-phased construction of a new 80’ x 59’ outdoor playground for children aged two to five years old.

One of the project objectives was to construct a welcoming school for students, faculty, and the greater community. Designed for students as young as three years old, the new classrooms have proper heights for toilets, drinking fountains, etc. and the new age-appropriate playground was constructed with safety in mind.

Project Highlights

- Project was completed utilizing three (3) different funding sources that had to be tracked and managed throughout the project.

- Our team was challenged with the availability of concrete. Worked with the contractor to get addition slab poured to allow work to continue throughout the Winter of 2021-22.

- Created innovative strategies to alleviate COVID induced supply constraints thus allowing the project to stay on schedule.

- Switched from traditional bar joists that had an extended lead time to all steel beam construction.